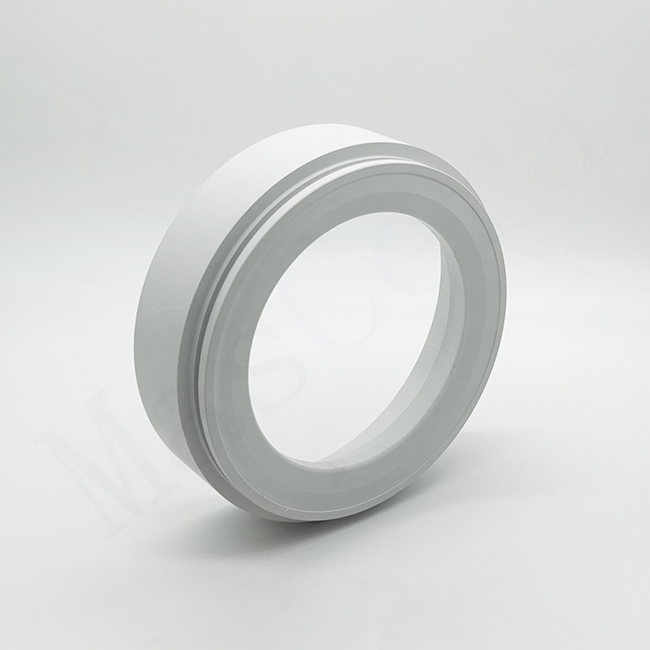

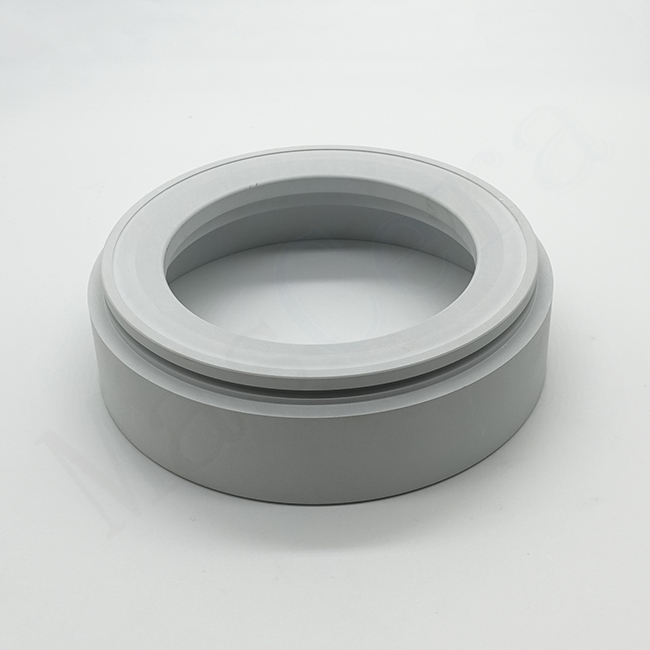

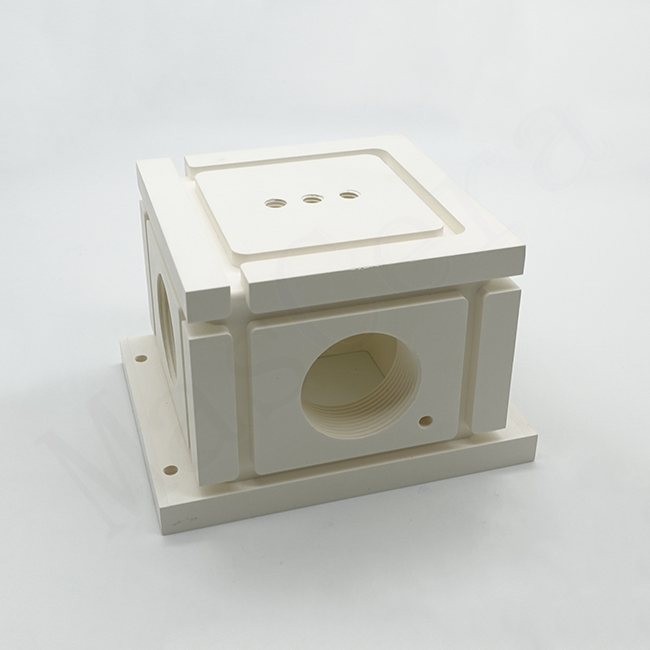

Anneau de rupture en nitrure de bore pour coulée continue horizontale

- MSJ/BN-011

- nitrure de bore pressé à chaud

- personnalisé

- 10 pièces par type

- Coulée continue horizontale

L'anneau de rupture Mascera BN-ZrO2 est un composant haute performance conçu pour les applications de coulée continue horizontale. Il est fabriqué à partir d'un matériau composite composé de nitrure de bore (BN) et de zircone (ZrO2), garantissant une fiabilité et une longévité exceptionnelles. Cet anneau de séparation joue un rôle essentiel dans le maintien d'un front de solidification stable et permet un retrait contrôlé du brin coulé.

Pour toute demande, veuillez envoyer un e-mail à info@mascera-tec.com ou appeler le +86 13860446139

Product detail

The Mascera BN-ZrO2 Break Ring is a high-performance component designed for horizontal continuous casting applications. It is constructed using a composite material comprising boron nitride (BN) and zirconia (ZrO2), ensuring exceptional reliability and longevity. This break ring plays a critical role in maintaining a stable solidification front and enabling controlled withdrawal of the cast strand.

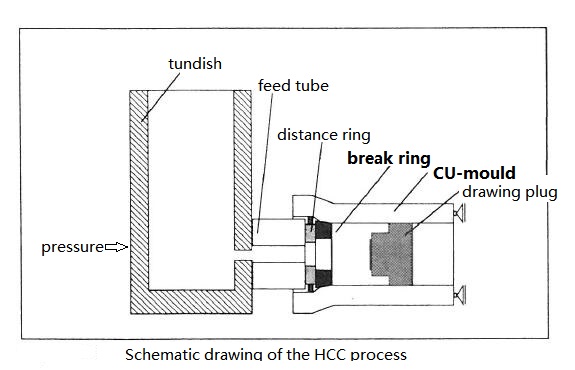

As shown in the process diagram of horizontal continuous casting (HCC), the connection between the tundish and the crystallizer water inlet is prone to severe erosion and thermal shock. One crucial element of horizontal continuous casting involves the movement of molten material from the holding crucible to the graphite die and cooler assembly, without relying on gravity. The molten material traverses through a graphite die, a series of holding components, and ultimately reaches the solidification zone by passing through a refractory ring known as the break ring. During the transition from the hot zone to the cool zone (solidification zone), where the temperature changes abruptly, it is of utmost importance for the break ring to maintain its integrity. It must enable the molten material to continue flowing smoothly without sticking or accumulating at the junction. Despite being a seemingly simple part of the entire assembly, break rings play a critical role in horizontal continuous casting. Any failure or breakage of these components would result in the loss of the entire heat, posing safety hazards and causing significant downtime for part replacement and cleanup.

material from the holding crucible to the graphite die and cooler assembly, without relying on gravity. The molten material traverses through a graphite die, a series of holding components, and ultimately reaches the solidification zone by passing through a refractory ring known as the break ring. During the transition from the hot zone to the cool zone (solidification zone), where the temperature changes abruptly, it is of utmost importance for the break ring to maintain its integrity. It must enable the molten material to continue flowing smoothly without sticking or accumulating at the junction. Despite being a seemingly simple part of the entire assembly, break rings play a critical role in horizontal continuous casting. Any failure or breakage of these components would result in the loss of the entire heat, posing safety hazards and causing significant downtime for part replacement and cleanup.

BN-ZrO2 break ring possesses critical properties such as high thermal shock resistance, low friction coefficient at high temperatures, and corrosion and slag resistance. These properties are essential for ensuring uninterrupted melt flow, facilitating build-up free movement, and accommodating a wide range of materials in the continuous casting process. The size and shape of the separation ring typically depend on the type of continuous casting equipment and the material being cast. Mascera can produce separation rings based on customer drawings and dimensional requirements.

For any inquiry, please feel free to email us at info@mascera-tec.com or call us at +86 13860446139.

Advantage of Boron Nitride Break Ring

1.Resistance to chemical corrosion from the molten metal.

2.Low wettability by the molten metal.

3.High wear resistance.

4.High resistance to thermal shock.

5.Low thermal conductivity.

6.Good machinability.

Material Data Sheet

| Item | Unit | BN-997 | BN-99 | BN-A | BN-B | BN-C | BN-D | BN-E | BN-S |

|---|---|---|---|---|---|---|---|---|---|

Main Content | - | BN>99.7% | BN>99% | BN+AL+SI | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+AlN | BN+Si3N4 |

Color | - | White | White | Light Grey | Light Grey | Grey Green | Dark Grey | Grey Green | Dark Grey |

Density | g/cm3 | 1.6 | 1.95-2.0 | 2.2-2.3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 | 2.2-2.3 |

Flexural Strength | Mpa | 18 | 30 | 65 | 65 | 80 | 90 | 90 | 150 |

Compressive Strength | Mpa | 45 | 85 | 145 | 145 | 175 | 220 | 220 | 380 |

Thermal Conductivity | W/Mk | 35 | 40 | 35 | 35 | 45 | 30 | 85 | 40 |

Thermal Expansion Coefficient (@25 - 1000℃) | 10-6/K | 1.5 | 1.8 | 2.0 | 2.0 | 2.8 | 3.5 | 2.8 | 2.7 |

Max. Service Temp. @Air Condition | ℃ | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

Max. Service Temp. @Vacuum Condition | ℃ | 1800 | 1800 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Max. Service Temp. @Inert Gas Condition | ℃ | 2100 | 2100 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Electrical Resistivity | Ω.Cm | >1014 | >1014 | >1013 | >1013 | >1012 | >1012 | >1013 | >1013 |

Emballage et expédition

| Type de colis | boîte en carton avec protection en mousse |

| Conditions de paiement | TT / Western Union / Paypal Paiement à 50% à l'avance et 50% avant expédition |

| Port de chargement | Xiamen, Chine |

| Mode d'expédition | Par mer / air / porte à porte express |

Nous sommes un fabricant professionnel de céramiques techniques, nous fournissons une production sur mesure à des prix compétitifs....more